Introduction:

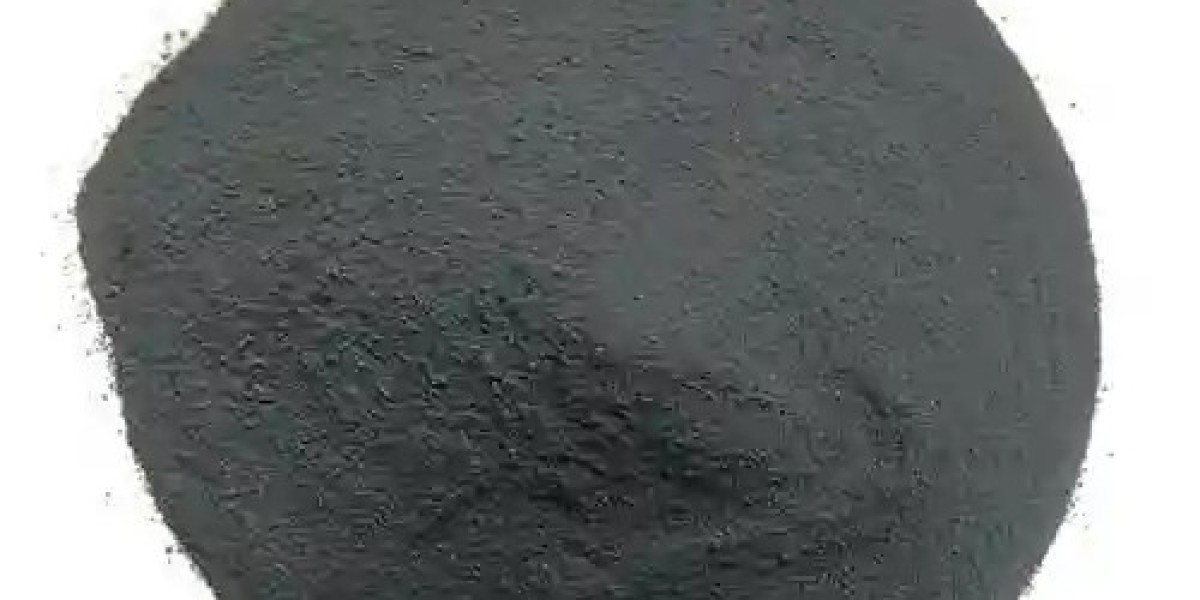

Silicafume Manufacturers in India, also referred to as microsilica, emerges as a byproduct of silicon metal or ferrosilicon alloy production. Its micron-sized particles, when meticulously incorporated into concrete formulations, engender profound enhancements in both strength and durability. In this comprehensive discourse, we illuminate the transformative potential of silica fume, delineating its merits, applications, and manufacturing standards.

The Science Behind Silica Fume:

Silica fume embodies a remarkable amalgamation of physical and chemical properties, underpinned by its high reactivity and amorphous silica composition. This finely particulate material boasts a surface area surpassing that of conventional cement particles, facilitating an accelerated pozzolanic reaction upon hydration. Within the concrete matrix, silica fume interacts with calcium hydroxide to engender additional calcium silicate hydrate (C-S-H) gel formation. The resulting microstructure exhibits heightened density and diminished porosity, heralding unparalleled strength and impermeability.

Empowering Strength:

At the heart of silica fume's prowess lies its capacity to bestow concrete with formidable compressive strength. The intricate network of bonds forged through the pozzolanic reaction imbues the material with superior mechanical properties, surpassing the confines of conventional mixes. Concrete fortified with Amorphous Silica Manufacturers in India epitomizes resilience, rendering it an indispensable asset for structural applications mandating uncompromising strength benchmarks.

Fostering Durability:

Durability constitutes a linchpin in the realm of concrete longevity, particularly in the face of adversarial environmental conditions. Silica fume emerges as a stalwart ally in fortifying concrete against myriad forms of deterioration. Its impervious matrix serves as a bulwark against chloride ingress, forestalling the specter of corrosion within reinforced concrete infrastructures. Furthermore, the curtailed permeability stemming from silica fume integration confounds threats posed by sulfate aggression and alkali-silica reaction, safeguarding the structural integrity over prolonged service life.

Exemplary Manufacturing Practices:

As vanguards of excellence within the domain of Silica Fume Manufacturers in India, we espouse a steadfast commitment to unparalleled quality and ingenuity throughout our manufacturing endeavors. Our production facilities are meticulously tailored to exacting standards, ensuring the consistent delivery of pristine silica fume products. By meticulously curating raw materials and employing cutting-edge manufacturing techniques, we epitomize a paradigm of manufacturing excellence that underpins our unwavering dedication to industry-leading solutions.

Conclusion:

In summation, the strategic deployment of silica fume emerges as a linchpin in the pursuit of optimal concrete performance. Its innate capacity to augment strength, fortify durability, and underpin sustainable construction practices underscores its indelible significance within the contemporary construction milieu. As custodians of innovation and reliability, we, as premier Micro Silica Manufacturers in India, remain steadfast in our mission to empower the construction fraternity with solutions that transcend the ordinary, fostering a landscape characterized by resilience, durability, and unwavering trust.